Crates, Reimagined

INNOV8TIVE SOLUTIONS

You imagine it, we create it.

Our Innov8 Model

Warehouse design, product shape and size, freight costs, business needs—these all changed over time but the storage crate industry stayed still. Not any longer. We’re disrupting industry standards and offering innovation as a service. Partnering with our clients and getting to know the ins-and-outs of their warehouse and storage needs, we work alongside you for the whole process, from design ideation to manufacturing and logistics coordination. Using our Innov8 Model, we upgrade your warehouse storage from the industry standard, to customized crates that suit your unique needs.

-

STEP 1Complete Project ManagementHelping companies succeed through innovation is what we do best. A one-size-fits-all approach doesn’t work for crates and it certainly doesn’t work for business. You need custom solutions that work for your unique operation. It’s about the crates, but it’s about so much more—cost savings, efficiency, warehouse noise reduction, and increased productivity to name a few. We offer end-to-end project management, including part design, mold design, manufacturer selection, production and delivery. More than a manufacturer, we partner without clients to create solutions that work.STEP 1Helping companies succeed through innovation is what we do best. A one-size-fits-all approach doesn’t work for crates and it certainly doesn’t work for business. You need custom solutions that work for your unique operation. It’s about the crates, but it’s about so much more—cost savings, efficiency, warehouse noise reduction, and increased productivity to name a few. We offer end-to-end project management, including part design, mold design, manufacturer selection, production and delivery. More than a manufacturer, we partner without clients to create solutions that work.

-

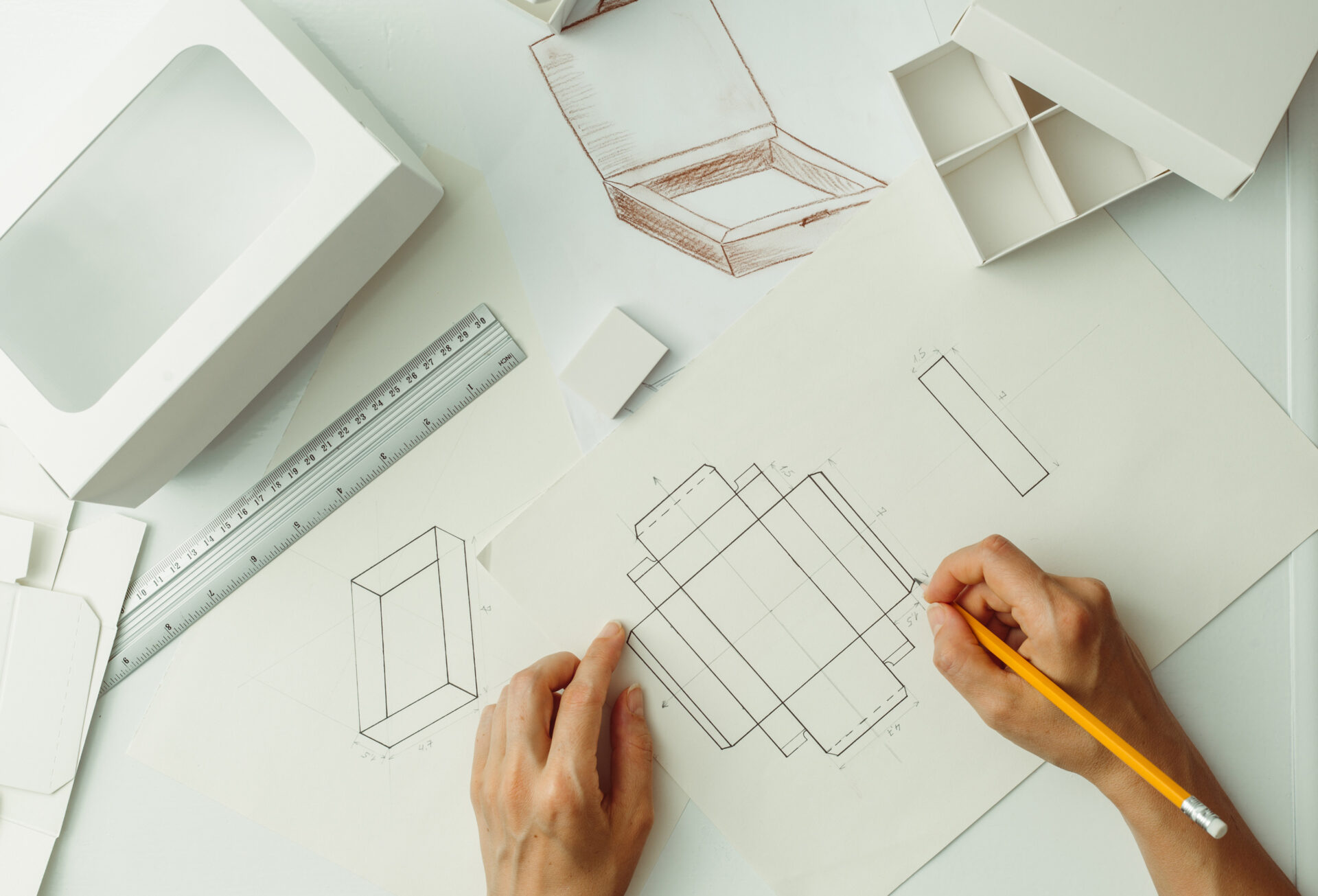

STEP 2Custom and Collaborative Part DesignCustomization starts with collaboration. To create solutions for your unique needs, first we need to assess your pain points via a discovery meeting and warehouse assessment. Knowing your challenges is only half of it, we want to know your vision for how your warehouse could be. Together, we’ll imagine what’s possible, then our team will take it further in the design phase to come up with a design that not only meets your needs, but exceeds your expectations.STEP 2Customization starts with collaboration. To create solutions for your unique needs, first we need to assess your pain points via a discovery meeting and warehouse assessment. Knowing your challenges is only half of it, we want to know your vision for how your warehouse could be. Together, we’ll imagine what’s possible, then our team will take it further in the design phase to come up with a design that not only meets your needs, but exceeds your expectations.

-

STEP 3Prototype Part DevelopmentBefore we move into full scale manufacturing, we’ll create a prototype to test the design. This is a crucial step that allows us to ensure our design truly solves your warehouse challenges.STEP 3Before we move into full scale manufacturing, we’ll create a prototype to test the design. This is a crucial step that allows us to ensure our design truly solves your warehouse challenges.

-

STEP 4Managed Mold ManufacturingWorking alongside our verified tooling partners, RollerPlast oversees the custom mold manufacturing process. Our team has a hand in every part of the process to ensure that every detail, no matter how small, is executed at a high level of precision and quality.STEP 4Working alongside our verified tooling partners, RollerPlast oversees the custom mold manufacturing process. Our team has a hand in every part of the process to ensure that every detail, no matter how small, is executed at a high level of precision and quality.

-

STEP 5T1 Samples for System Testing and ValidationBy creating samples of our custom molds, we are able to test and validate the design before going into full scale production. Every mold is quality control tested, ensuring that the end product—your custom crate—stands up to our exacting standards.STEP 5By creating samples of our custom molds, we are able to test and validate the design before going into full scale production. Every mold is quality control tested, ensuring that the end product—your custom crate—stands up to our exacting standards.

-

STEP 6100% Domestic ManufacturingKeeping our injection molding partners domestic allows us to offer savings and stability to our clients. Onshoring reduces cost of shipping, allows for just-in-time delivery and reduces supply chain risks. We’ve partnered with major injection molders across the United States, strategically located to serve our growing number of clients.STEP 6Keeping our injection molding partners domestic allows us to offer savings and stability to our clients. Onshoring reduces cost of shipping, allows for just-in-time delivery and reduces supply chain risks. We’ve partnered with major injection molders across the United States, strategically located to serve our growing number of clients.

-

STEP 7Proximity ManufacturingPartnering with injection molding manufacturers across the United States allows us to bring our manufacturing closer to our clients all across the country—often in their own state. This system effectively reduces shipping costs and speeds up delivery times. Our manufacturing partners are thoroughly tested and vetted to ensure they produce products consistent with our high standards.STEP 7Partnering with injection molding manufacturers across the United States allows us to bring our manufacturing closer to our clients all across the country—often in their own state. This system effectively reduces shipping costs and speeds up delivery times. Our manufacturing partners are thoroughly tested and vetted to ensure they produce products consistent with our high standards.

-

STEP 8Logistics Coordination Through ImplementationWorking with your installation team we provide solutions to inefficiencies and improve operations, all while reducing costs. We are able to offer just-in-time delivery and smaller quantity orders, ensuring you have the crates you need, but not having to store excess.STEP 8Working with your installation team we provide solutions to inefficiencies and improve operations, all while reducing costs. We are able to offer just-in-time delivery and smaller quantity orders, ensuring you have the crates you need, but not having to store excess.

-

OUR LEADERSHIP TEAM

Backed by 50 years of industry experience, our team is rewriting the rules of industrial crate design.

RollerPlast is the result of innovative minds and industry experience coming together to disrupt a stagnant industry and provide better solutions for warehouse organization. While warehouse design and consumer products have evolved over the last few decades, industrial crate design has stayed the same. Our leadership team saw an opportunity to redefine standards and created our Innov8 model to shake up the warehouse industry.

You don’t have to settle for standardized crates anymore—we’ve created a better option. Custom. RollerPlast works with clients to create custom crates that provide innovative solutions to your warehouse challenges. As a team, we aren’t just bringing industrial crates to the present, we’re taking them to the next level.

Clark Chow

Senior Partner

Justin Elvin-Jensen, BComm

Senior Partner & Designer

Scott Vigliotti, MBA

VP Operations

Manveer Pattar, MBA

Director of Operations